Industrial Metaverse: 7 Brilliant Ways It Is Revolutionizing Global Factories

On This Page

Industrial Metaverse implementation has quickly become the gold standard for organizations seeking to eliminate the massive costs associated with physical trial and error. For decades, manufacturing was a reactive industry, where problems were often only discovered after a production line was already live. Today, the ability to merge real-world data with high-fidelity virtual environments allows for a “connected whole-system” approach. This immersive ecosystem enables a level of industrial intelligence that was previously impossible, allowing manufacturers to move away from reactive fixes toward predictive, autonomous control.

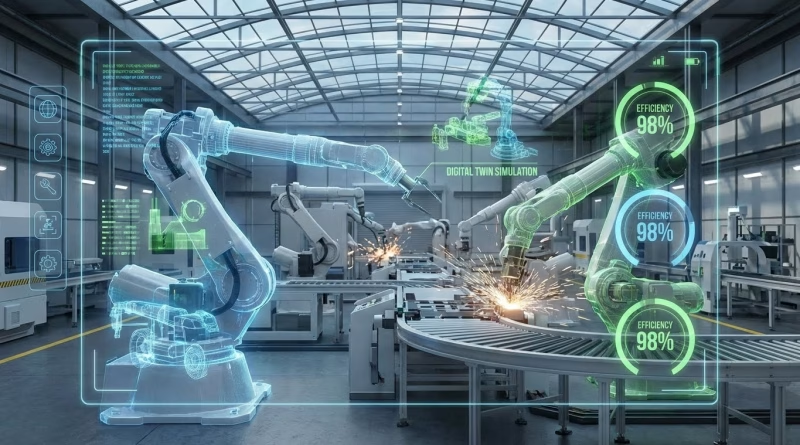

The Brilliant Precision of Industrial Metaverse Digital Twins

At the very heart of this transformation is the digital twin, the primary building block of any Industrial Metaverse strategy. Unlike a static 3D model, a digital twin is a living “mirror” that reflects and enhances physical operations in real-time. By connecting sensors on the factory floor to a virtual replica, engineers can monitor machine behavior with unprecedented accuracy.

This level of detail allows for a significant leap in predictive maintenance. Instead of waiting for a critical component to fail, the Industrial Metaverse enables the system to simulate wear and tear based on actual usage data. This foresight allows teams to intervene before a breakdown occurs, ensuring that production remains uninterrupted and maximizing the lifespan of expensive industrial assets.

How the Industrial Metaverse Solves Global Manufacturing Friction

The true power of the Industrial Metaverse lies in its ability to act as a “crystal ball” for factory planning and operational scaling. Global leaders are no longer building physical prototypes to test new layouts; they are running millions of design iterations in a physics-based virtual environment. This “virtual sandbox” allows engineers to identify up to 90% of potential bottlenecks and safety hazards long before a single brick is laid or a machine is bolted to the floor.

By utilizing the Industrial Metaverse, companies like PepsiCo have reported throughput increases of up to 20% while simultaneously reducing capital expenditure. When you can simulate the impact of a new assembly line virtually, the risk of a “failed launch” is virtually eliminated. This efficiency is what makes the Industrial Metaverse a revolutionary asset for any company operating on a global scale.

Driving Sustainability Through Industrial Metaverse Simulation

Environmental stewardship is now a non-negotiable priority for modern industry, and the Industrial Metaverse is the most effective tool for reaching net-zero goals. By visualizing resource consumption, heat waste, and carbon emissions in a virtual space, companies can engage in hyper-efficient operational planning.

The Industrial Metaverse assists in quantifying environmental loads and simulating various energy-saving scenarios before they are executed in reality. This integration of digital technology reduces physical waste and optimizes energy flow across the entire value chain. In a world where sustainability directly impacts the bottom line, the Industrial Metaverse provides the data-driven insights needed to build a resilient and eco-friendly manufacturing ecosystem.

Safety Gains and Human-Centric Industrial Metaverse Training

The transition toward newer industrial paradigms highlights a change in thinking, shifting from a system dominated by pure automation to one that prioritizes the human element within the Industrial Metaverse. Immersive training is a standout use case, providing workers with realistic simulations of complex manufacturing processes and high-risk safety scenarios without any real-world danger.

Employees can step into the Industrial Metaverse to become familiar with new equipment or emergency protocols in a digital format. This ensures that when they step onto the actual factory floor, they are already experts in the task at hand. This human-centric approach turns the Industrial Metaverse into a tool that boosts human capabilities, leading to a massive reduction in workplace accidents and a more skilled, confident workforce.

The Future Architecture of Industrial Metaverse Networks

As we look toward the future, the integration of AI agents directly into the Industrial Metaverse will lead to truly autonomous “smart factories.” These systems will no longer just report data; they will make real-time adjustments to eliminate inefficiencies as they happen. The Industrial Metaverse serves as the nervous system for this new era, connecting every sensor, machine, and person into a single, intelligent network.

The most successful manufacturers are no longer those with the most expensive machines, but those who have mastered the data flow within their Industrial Metaverse environments. By simulating “thousands of trials” in the virtual world, the industrial sector is reclaiming its agility and setting a new global standard for innovation and productivity.