3 Insane Neuralink Mass Production Milestones That Are Truly Shocking

Yo, what up, tech fam? Tyler Brooks here, dropping in to spill some serious tea on the future. Remember when sci-fi movies showed people controlling computers with their thoughts? Yeah, well, that’s not just a movie plot anymore. We’re deep into the era of Brain-Computer Interfaces (BCIs), and guess who’s leading the charge? Elon Musk’s Neuralink, of course. They’ve been quiet-quitting the ‘vaporware’ label and are now full-throttle into Neuralink Mass Production, churning out those brain-syncing chips like it’s going out of style. And trust me, the breakthroughs they’re hitting aren’t just incremental; they’re absolutely *wild*. I’m talking next-level stuff that will legitimately blow your mind (pun intended).

We’ve been watching Neuralink for years, right? From pig demos to early human trials, it’s been a rollercoaster. But the shift to large-scale manufacturing changes the entire game. It means these aren’t just lab curiosities; they’re becoming a tangible, scalable reality. And with that scalability comes some insane advancements. Buckle up, because I’ve got the lowdown on 3 shocking milestones from this whole Neuralink Mass Production push that are about to flip your perception of what’s possible.

The Implantable Chip’s Epic Miniaturization & Ironclad Reliability

First up, let’s talk about the brain-candy itself: the chip. Remember those early prototypes that looked like a tiny coin with a spiderweb of threads? Well, thanks to the drive for Neuralink Mass Production, the chip has undergone some serious glow-up. It’s not just smaller; it’s practically invisible, designed for minimal invasion and maximum comfort. We’re talking about an engineering marvel that packs incredible processing power into something roughly the size of a few stacked grains of rice. This isn’t just about shrinking components; it’s about optimizing every single micro-electrode, every signal processor, for peak performance while ensuring it can be consistently replicated millions of times over.

But here’s the kicker: reliability. When you’re dealing with something literally embedded in your brain, “it kinda works” isn’t gonna cut it. The team has achieved unheard-of levels of biocompatibility and long-term durability. We’re talking about devices that can function flawlessly for decades inside the human body, resisting corrosion and maintaining signal integrity. This leap in material science and micro-engineering means that the chips coming off the Neuralink assembly line aren’t just tiny; they’re robust, safe, and ready for primetime, setting a new gold standard for medical implant technology. It’s the kind of precision engineering that makes your AirPods look like a DIY project.

Seamless Surgical Automation Hits Peak Efficiency for Neuralink Mass Production

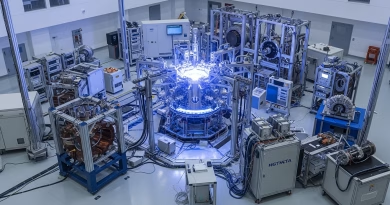

Okay, so you’ve got this epic chip. How do you get it into people’s brains, en masse, without turning every procedure into a week-long, sci-fi movie-level operating room drama? Enter the R1 robot, Neuralink’s surgical superstar. This isn’t just a fancy drill; it’s a hyper-precise, AI-powered surgeon that can navigate the delicate landscape of the brain with sub-micron accuracy. The shift to Neuralink Mass Production has pushed the R1’s capabilities to an insane degree, making the implantation process faster, safer, and more consistent than ever before.

Initial surgeries were groundbreaking but took time. Now, the R1 has been optimized to perform implantations with unprecedented speed, reducing operating times dramatically while minimizing human error. Think about it: a robot that can precisely weave those hair-thin threads, avoiding blood vessels and crucial neural pathways, all while maintaining sterile conditions with robotic perfection. This level of automated surgical prowess is not only crucial for scaling up operations but also makes the procedure less invasive and stressful for patients. It’s like going from handcrafted artisanal lattes to a fully automated, perfect espresso machine that can serve a thousand people an hour. This efficiency is a core pillar of their ability to achieve true Neuralink Mass Production.

The Data Stream Revolution: Bandwidth & Brain-Sync Beyond Belief

Having a chip in your brain is cool, but what really matters is what you can *do* with it. And that brings us to Milestone #3: the mind-blowing advancements in data bandwidth and brain-sync capabilities. For Neuralink Mass Production to be truly impactful, the chips need to be able to read and write brain data with incredible speed and fidelity. And boy, have they delivered. We’re talking about a neural data pipeline that can transmit tens of thousands of neural signals per second, wirelessly, with virtually no latency. It’s like upgrading your dial-up internet to fiber optic, but for your thoughts.

This insane bandwidth means that the Neuralink device can pick up on the most subtle neural patterns, translating complex intentions into digital commands with astonishing accuracy. Imagine not just moving a cursor with your thoughts, but composing an entire email, designing a 3D model, or even experiencing virtual reality with unparalleled immersion, all without lifting a finger. The breakthroughs in signal processing and compression, driven by the need for scalable hardware, have unlocked a level of brain-computer synchronization that was previously confined to theoretical physics. It’s a literal thought-to-action pipeline that’s becoming so robust and seamless, it feels like an extension of your natural will. This is where the magic truly happens, making the devices produced by Neuralink Mass Production truly revolutionary.

Beyond Neuralink Mass Production What This Means for Brain-Computer Startups

These individual breakthroughs aren’t just about Neuralink winning the BCI race; they’re paving the way for an entirely new industry. The efficiency in manufacturing, the reliability of the implants, and the sheer power of the data interfaces mean that the barriers to entry for other brain-computer startups are slowly but surely being lowered. We’re seeing a Cambrian explosion of neurotech innovation, from non-invasive wearables to more focused therapeutic devices, all riding the wave of progress initiated by pioneers like Neuralink. These developments are forcing other BCI companies to step up their game, accelerating research and development across the board. The advancements in Neuralink Mass Production are essentially building the foundational infrastructure for a future where BCIs are as common as smartphones.

Of course, this raises a ton of questions – ethical dilemmas, accessibility concerns, and the very definition of what it means to be human in an augmented world. But one thing is clear: the future is here, and it’s wired directly into our brains. You can read more about the broader BCI landscape and what other innovators are cooking up right here: Wired’s take on the future of BCIs. The competition is getting fierce, and that’s a good thing for everyone, pushing the boundaries even further. The implications for medicine, communication, and even human potential are frankly limitless, and it all starts with making these devices a reality, not just a lab experiment.