10 Explosive Ways Warehouse Robotics Is Delivering Amazing Efficiencies

From the industrial revolution’s mechanical looms to the early 20th century’s conveyor belts, the evolution of human industry has been a relentless march towards optimized production and distribution. Yet, even as recently as a decade ago, the beating heart of global commerce – the warehouse – remained largely a realm of human muscle and manual dexterity. Today, that paradigm is undergoing a revolutionary transformation. The advent of physical AI, manifested through advanced warehouse robotics, is not merely optimizing operations; it’s fundamentally redefining the very architecture and operational logic of modern logistics. This isn’t just an upgrade; it’s a seismic shift, promising unprecedented levels of speed, accuracy, and scalability. In this deep dive, we’ll explore 10 incredible ways these intelligent machines are delivering amazing efficiencies and shaping the future of supply chains.

Unleashing Unprecedented Efficiency with Warehouse Robotics

The immediate and most visible impact of warehouse robotics lies in their ability to dramatically accelerate throughput and streamline internal processes. Gone are the days of manual picking routes and human error dictating the pace of operations. Robots operate with tireless precision, 24/7, fundamentally altering the calculus of productivity.

- Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs): These are the workhorses of the modern automated warehouse. AGVs follow predefined paths, excellent for repetitive bulk movements. AMRs, however, represent a leap forward, utilizing sophisticated sensors and AI to navigate dynamic environments, avoid obstacles, and plot the most efficient routes in real-time. They carry goods, move pallets, and even ferry inventory to human workers, vastly reducing travel time and manual effort.

- Robotic Picking and Palletizing: One of the most physically demanding and repetitive tasks is now handled by sophisticated robotic arms. Equipped with advanced vision systems and grippers, these robots can identify, pick, and place a vast array of items, from individual products to entire cases, with astonishing accuracy and speed. They can also assemble pallets with perfect precision, optimizing space and stability for shipping.

- Automated Storage and Retrieval Systems (AS/RS): These towering, complex systems are the epitome of high-density storage. Utilizing robotic cranes and shuttles, AS/RS can retrieve and store items in vertical structures that would be inaccessible to humans, optimizing cubic space like never before. This not only saves floor space but also significantly speeds up the retrieval process, feeding items directly to picking stations when needed.

- Drone-based Inventory Management: Taking efficiency to new heights, literally, drones are being deployed to conduct rapid, accurate inventory counts. Equipped with RFID readers and cameras, these aerial robots can scan thousands of locations in minutes, reaching shelves too high or dangerous for human access, providing real-time stock levels and significantly reducing the time and labor associated with traditional inventory checks.

Elevating Safety and Ergonomics in Modern Warehouses

Beyond sheer speed, the deployment of warehouse robotics introduces a profound shift in workplace safety and employee well-being. By automating hazardous or monotonous tasks, warehouses are becoming safer, more ergonomic environments for human workers.

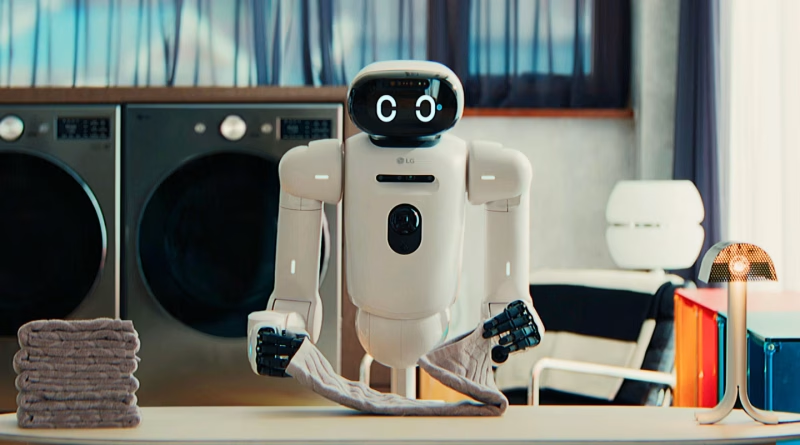

- Collaborative Robots (Cobots): Designed to work safely alongside humans, cobots are revolutionizing task allocation. They can handle repetitive, heavy lifting, or physically demanding processes, freeing human workers to focus on more complex, decision-making, or customer-facing roles. This not only reduces the risk of musculoskeletal injuries but also enhances job satisfaction by re-skilling the workforce.

- AI-powered Vision Systems for Quality Control: Human inspection, while vital, is prone to fatigue and subjective error. AI-powered vision systems, integrated into robotic workflows, can perform meticulous quality checks on incoming goods or outgoing packages. They can detect damage, verify labels, and ensure product integrity with unwavering consistency, significantly reducing costly errors and returns. The precision offered minimizes human exposure to potentially faulty or mispackaged items, contributing to overall safety.

The impact of robotics on worker safety is a field of ongoing research and development, with organizations like OSHA providing guidelines for safe human-robot collaboration, highlighting the critical importance of proper integration and training.

The Intelligence of Inventory and Operational Transparency

The true power of physical AI in logistics extends beyond mere automation to intelligent data capture and analysis. Robots are not just movers; they are data collectors, feeding insights that optimize the entire supply chain.

- Predictive Maintenance for Robotics: Downtime is costly. AI algorithms analyze data from robotic sensors to predict potential mechanical failures before they occur. This allows for proactive maintenance, scheduling repairs during off-peak hours, and ensuring continuous operation, thereby maximizing uptime and efficiency across the entire warehouse robotics fleet.

- Dynamic Route Optimization: Human planners, however skilled, cannot process the sheer volume of variables required for optimal pathfinding in real-time. AI-driven systems continuously analyze order queues, robot locations, and warehouse layouts to dynamically optimize the routes for AGVs and AMRs. This ensures the fastest possible movement of goods, reduces congestion, and adapts instantly to changing conditions or priorities.

- Data Analytics for Warehouse Operations: Every movement, every scan, every pick performed by a robot generates valuable data. AI platforms aggregate and analyze this data to provide deep insights into warehouse performance. This includes identifying bottlenecks, optimizing inventory placement, predicting demand fluctuations, and refining operational strategies, leading to continuous improvement and cost savings.

Scaling Operations and Adapting to the Unpredictable

In a world characterized by fluctuating consumer demands and unpredictable global events, the ability to scale operations rapidly and efficiently is paramount. Robots offer an unprecedented level of flexibility that traditional, human-centric warehouses struggle to match.

The modular nature of many robotic systems allows warehouses to expand or contract their operational capacity with relative ease. During peak seasons, additional robots can be integrated into the existing fleet to handle surges in order volume without the extensive recruitment and training overhead associated with manual labor. Conversely, during slower periods, robots can be repurposed or scaled back, offering significant cost savings. This adaptability is critical for businesses navigating the volatile landscape of modern commerce, ensuring they can meet demand without overcommitting resources. Furthermore, the inherent reconfigurability of robotic systems means that warehouse layouts can be adjusted more readily to accommodate new product lines, changing inventory profiles, or evolving fulfillment strategies, providing an agile response to market dynamics.

The Evolving Human-Robot Partnership in Warehouse Logistics

While often sensationalized as job destroyers, the reality of physical AI is a redefinition of human roles within logistics. The implementation of warehouse robotics isn’t about replacing humans wholesale, but rather about creating a more synergistic partnership that leverages the strengths of both.

As robots handle the heavy lifting, repetitive tasks, and intricate movements, human workers are transitioning into roles that demand higher-level cognitive functions. This includes robot oversight, maintenance and troubleshooting, programming and system integration, data analysis, and strategic planning. The focus shifts from brute force to brainpower, fostering a more skilled and engaged workforce. This evolutionary trajectory of human labor within automated environments is a testament to technology’s capacity not just to automate, but to elevate, creating new opportunities and demanding new competencies. The future of logistics is not merely automated; it is intelligently collaborative.